Reconditioned die cutting machines from renowned manufacturers as an economical alternative

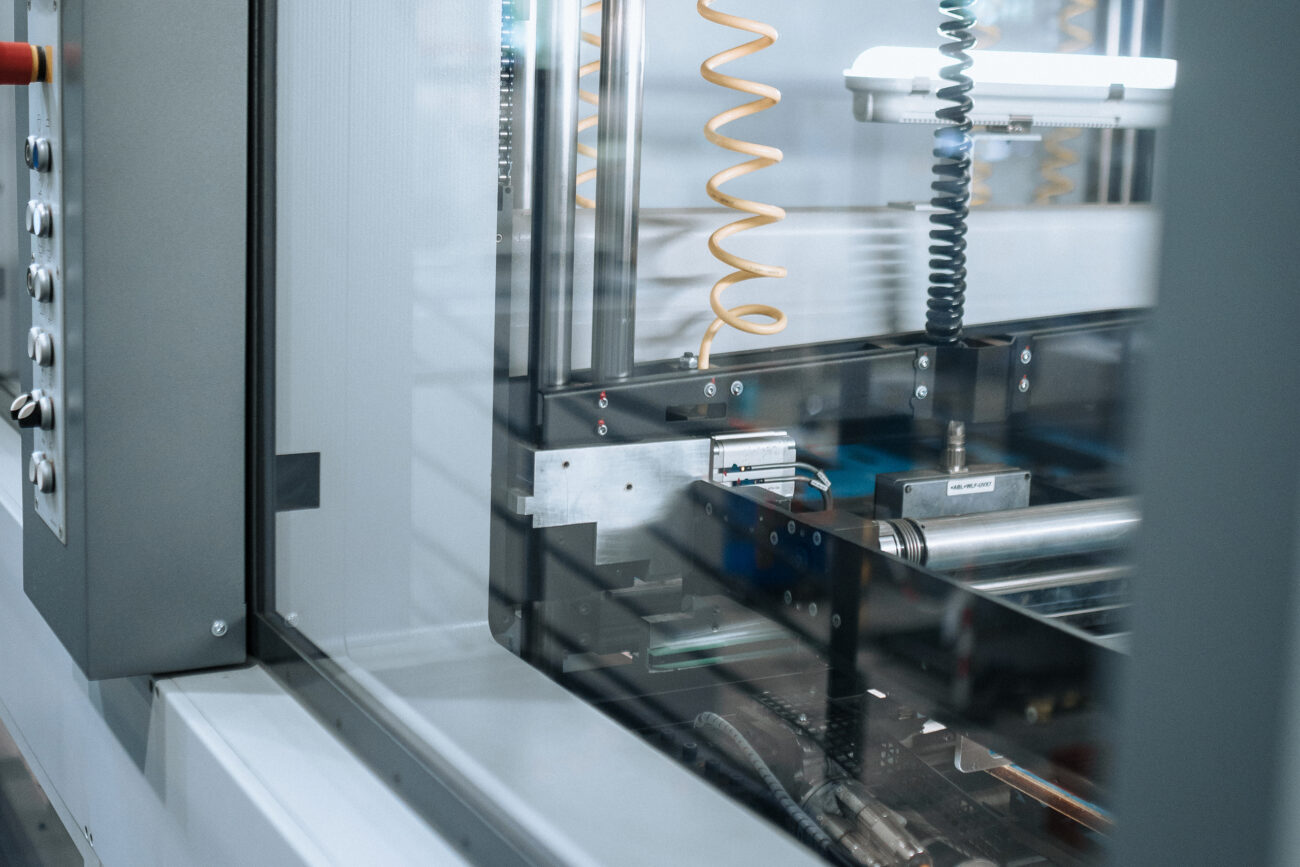

From HEIDELBERG to WPM and WUPA. Used die cutting machines from very different years of manufacture and with the most diverse equipment regularly find their way into the halls of QTM to undergo a careful inspection here. Because after a general overhaul, the large machines are ready for use again and ready to be used for years to come at a new location. And this is exactly the service that QTM offers: we take on the professional overhaul of die cutting machines for paper, cardboard and corrugated board processing.

From testing to complete cleaning, mechanical and electrical overhaul and painting, we provide the entire service in-house at QTM. We do not see ourselves as a used machine dealer, but much more as a consultant, partner and companion for the needs and concerns of our customers, which is why our die cutting machines leave QTM with a warranty of up to 12 months. To ensure that the machines are also put into operation as quickly as possible and can be used effectively, our first-class assembly team is also happy to provide on-site assembly service.

Professional overhaul and reconditioning work

Each project is individual

The necessary reconditioning work on a used punching machine varies greatly and depends on the respective machine and the customer-specific requirements. Individual rebuilds are also part of our service portfolio. After reconditioning, all punching machines are an economically attractive alternative to new machines. If desired, there is always the possibility of a customer acceptance test with customer material at our QTM plant in Schwalmtal.

Professional cleaning

- Disassembly of the cladding parts

- cleaning of the punched body, feeder in our washing cabin

- Cleaning of all small parts by hand

- reconditioning and painting of machines and cladding parts

- as well as many other individual tasks depending on the machine

Technical preparation

- Renewal of wear parts

- Replacement of defective parts

- Overhaul of the gripper carriages

- rail system/chain guides are converted to the system patented by QTM

- as well as many other individual tasks depending on the machine

Currently we have the following die cutting machines:

| Sequence Number | Info | Format | Velocity | Punching force | Year | Actions | |

|---|---|---|---|---|---|---|---|

|

Jagenberg Faltschachtel-Klebemaschine Diana 105-2 Takteinleger und Friktionseinleger; 1 Vibrator und 2 Blasdüsen für Zubringer; Unterleimwerk mit 5 mm Leimscheibe; Faltstation; Einfädelstation; Überleitstation |

900 x 1050 mm | 450 M/m | - MN | 1991 | Open datasheet Request now | |

|

Stanz- und Prägesystem Dymatrix 105 CS Pro Hochleistungs-Bogenanleger W 4; vollautomatisches Stanzen, Rillen und Prägen mit oder ohne Greiferrand; Moderne Siemenssteuerung S7; mit Centerline-Ausrüstung; Bedienpodest |

740 x 1050 mm | 9.000 B/h | 2.6 MN | 2004 | Open datasheet Request now | |

|

Stanz- und Prägesystem WPM 400 C Matic Hochleistungs-Bogenanleger W3; automatische Non-Stopp-Einrichtung zum vollautomatischen Stanzen, Rillen und Prägen; zum Nutzentrennen; mit einer Paketstapelmaschine; mit Centerline-Ausrüstung; Standard-Podest |

820 x 1130 mm | 9.000 B/h | 4,0 MN | 1999 | Open datasheet Request now | |

|

Stanztiegel Rabolini IMPERIA G Pneumatisches Brems-Kupplungssystem mit Sicherheitsventil; Zeitschaltuhr am Schaltpult; Öffnungszeit der Tiegelwippe regulierbar; Stückzähler; automatische Zentralschmierung, durch elektrische Ölpumpe, mit Taktbetrieb; Ölauffangwannen |

1250x 1960 mm | 850 B/h | - MN | 1999 | Open datasheet Request now | |

|

100-050 | WPM 300 II Ausbrechstation; Greiferrandabtrennvorrichtung; Nutzentrennstation, Paketstapeleinrichtung, Centerline |

740 x 1050 mm | 9.000 B/h | 2,6 MN | 1995 | Open datasheet Request now |

|

100-073 | HEIDELBERG Dymatrix 145 CSB stripping station, blank seperation, Centerline, automatic pallet changeover in delivery, patented QTM guide rail system, upgrde PLC to Siemens S7 |

1060 x 1450 mm | 8.000 B/h | 6,0 MN | 2009 | Open datasheet Request now |

|

100-071 | HEIDELBERG Dymatrix 106 CSB DySet Pro Balkenanlage, Ausbrechstation; Greiferrand-u. Nutzentrennung; Centerline; vollautomatische PWE in der Ablage, patentiertes QTM Schienensystem |

760 x 1060 mm | 9.000 B/h | 3,3 MN | 2006 | Open datasheet Request now |